Description

Pure Graphene Flakes Powder for Limitless Possibilities

Attention graphene enthusiasts! Are you on the lookout for top-quality graphene flakes that guarantee outstanding performance in a wide range of applications? Look no further than NanoEMI’s graphene flakes, where purity takes center stage!

Purity is a crucial factor to consider when selecting graphene flakes, and at NanoEMI, we pride ourselves on delivering graphene flakes with unparalleled purity levels. We understand that minimal impurities pave the way for exceptional performance in various applications, giving you the competitive edge you desire.

Our graphene flakes undergo rigorous quality control measures to ensure the highest purity standards. With meticulous attention to detail, we meticulously eliminate impurities, allowing our graphene flakes to shine with unmatched performance capabilities.

But what does this mean for you?

It means that by choosing NanoEMI’s graphene flakes, you’re opening the doors to a world of possibilities. Experience enhanced electrical conductivity, superior mechanical strength, and exceptional thermal properties. Witness the transformative power of high-purity graphene in energy storage, electronics, composites, and beyond.

Don’t compromise when it comes to purity. Trust NanoEMI’s graphene flakes to deliver the highest quality and unlock the full potential of your applications. Our commitment to excellence and unwavering dedication to producing the purest graphene flakes sets us apart as industry leaders.

Join the graphene revolution with NanoEMI’s pure graphene flakes. Elevate your projects to new heights and achieve unparalleled performance. Experience the future of graphene today!

Lead time

If the ordered product is currently in stock, it will be dispatched within 1-2 business days once the payment has been recorded or a proof of payment has been provided.

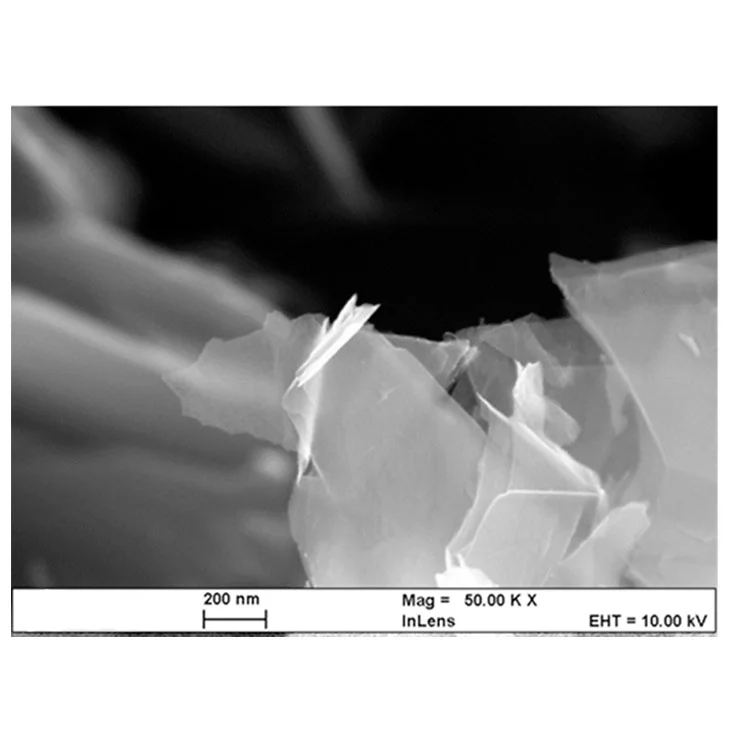

Scanning Electron Microscope (SEM) of Few Layer Graphene

SEM (Scanning Electron Microscopy) measurements are vital for analyzing the structure, thickness (number of graphene layers), and diameter of graphene flakes. This microscopy technique utilizes an electron beam to observe and analyze objects at the micrometer and nanometer scale. By scanning the sample surface with focused electrons, SEM produces high-resolution images with a large depth of focus, allowing for detailed spatial examination.

Quality Control at its Finest: Leveraging SEM for Surface Evaluation and Morphological Analysis of Graphene Flakes

At NanoEMI, we rely on SEM examination as a key tool to assess the surface condition and morphology of our graphene flakes. It works in tandem with other analysis methods to ensure stringent quality control and deliver high-quality graphene products.

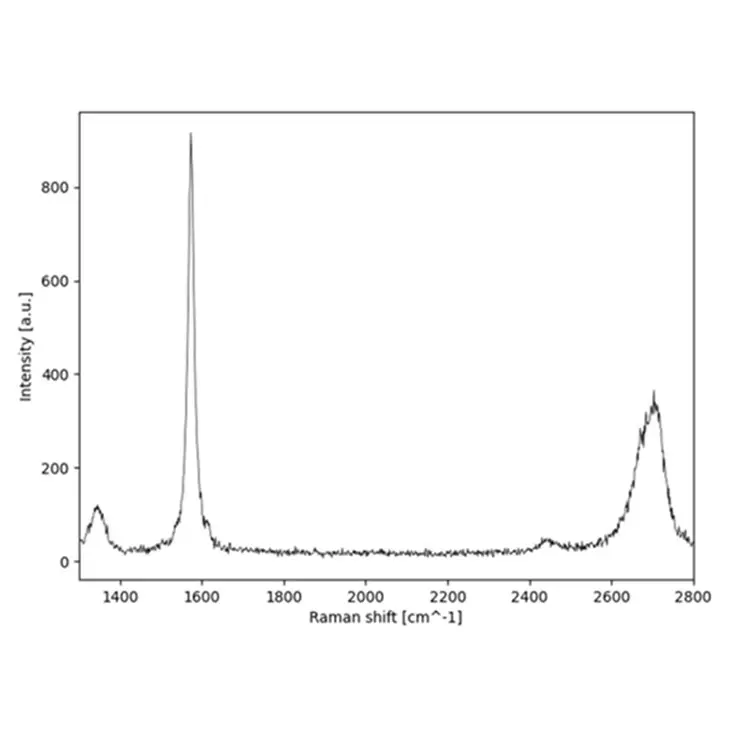

Raman Spectrum of MultiLayer Graphene

Raman spectroscopy is a non-destructive technique that measures the interaction of light with graphene’s vibrational modes. It provides information about the number of graphene layers, the presence of defects, and the degree of strain.

This spectroscopic technique involves measuring the inelastic scattering of photons, known as Raman scattering radiation, when a monochromatic light source interacts with the sample.

Precision and Consistency: Harnessing Raman Spectroscopy for High-Quality Graphene Flake Production

Raman spectroscopy plays a crucial role in ensuring the quality of graphene flakes production here at NanoEMI. By employing this technique, we can effectively analyze various aspects of the graphene flakes, providing valuable insights into their structural properties and overall quality.

Raman spectroscopy provides us with valuable insights into the quality and consistency of our graphene production, enabling us to maintain a reliable and consistent supply of top-grade graphene materials.

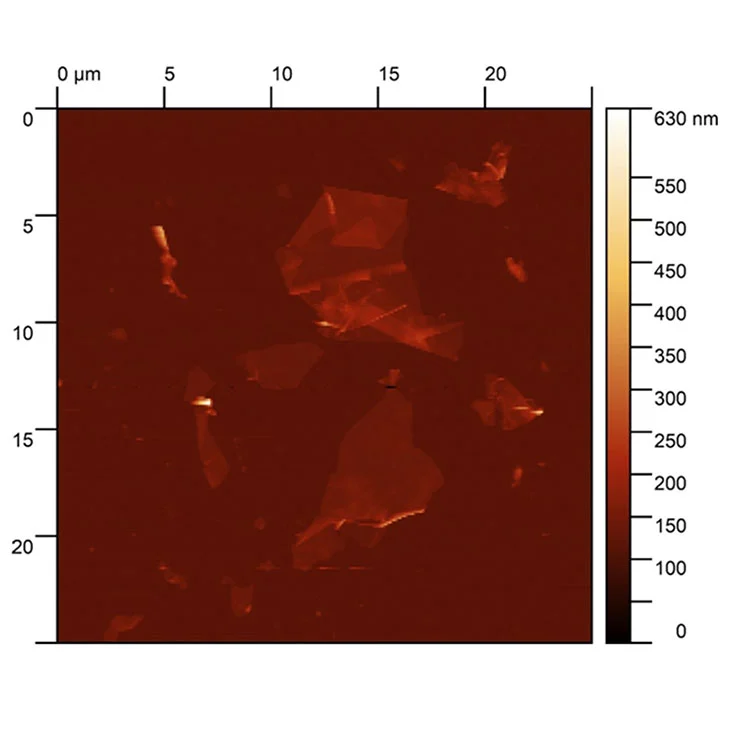

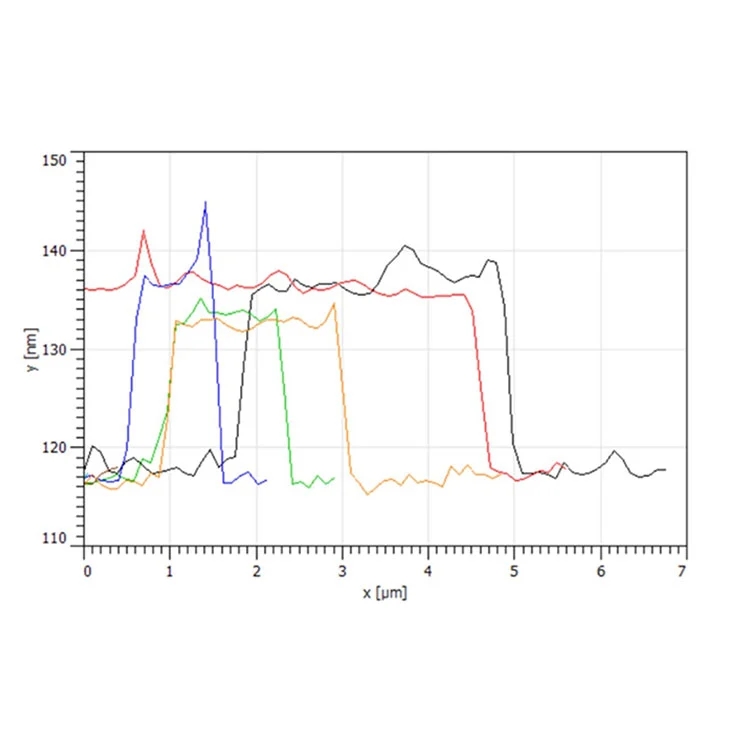

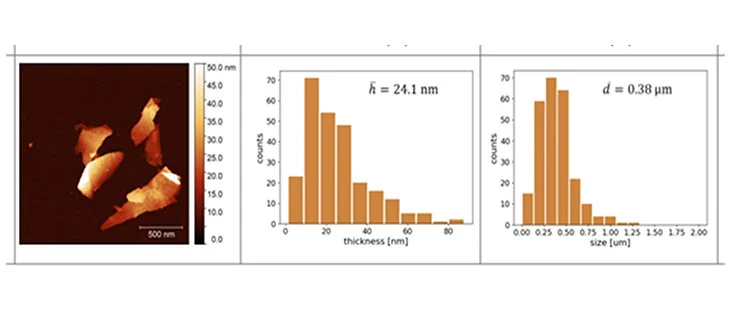

View from Atomic Force Microscope (AFM) of MultiLayer Graphene

As a leading graphene producer, we utilize Atomic Force Microscopy (AFM) as a crucial technique to ensure the quality of our MultiLayer graphene flakes. AFM allows us to analyze the surface morphology, thickness, and structural characteristics of the graphene flakes at the nanoscale.

Unleashing the Power of AFM: Ensuring Consistent Quality in Graphene Flakes Production

By employing a sharp probe that scans the sample surface, AFM measures the forces between the probe and the graphene flakes, creating high-resolution images and precise topographic data. This enables us to assess the uniformity, layer thickness, and integrity of the graphene flakes, ensuring consistent quality in our production.

The detailed information obtained from AFM analysis helps us optimize our manufacturing processes and quality control procedures. By leveraging AFM’s capabilities, we can confidently deliver MultiLayer graphene flakes of exceptional quality, meeting the stringent requirements of various industries, including electronics, energy, and materials science.

At NanoEMI, we are committed to utilizing cutting-edge technologies like AFM to ensure that our MultiLayer graphene products meet the highest standards of quality, performance, and reliability.

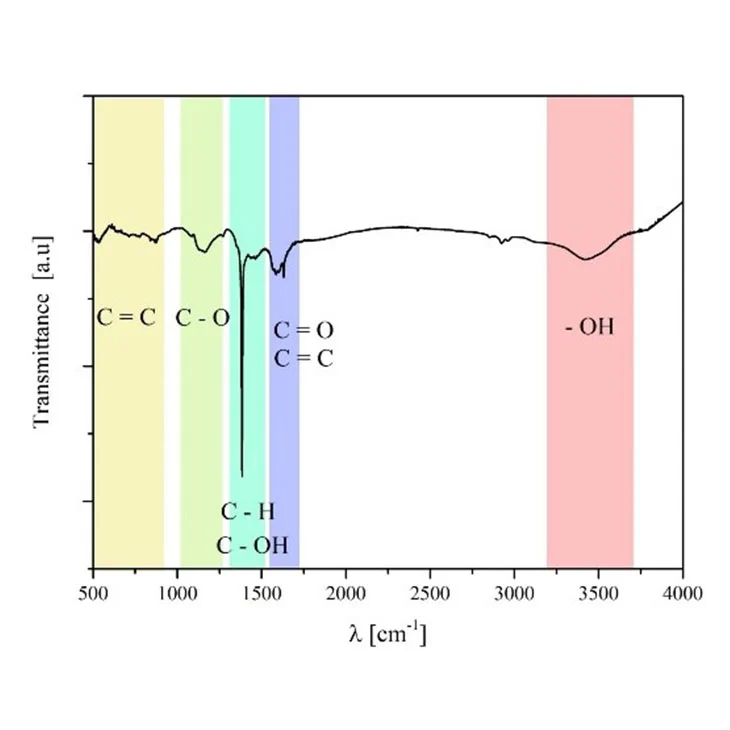

Fourier transform infrared spectrum (FTiR) of MultiLayer Graphene

At NanoEMI, we rely on Fourier Transform Infrared Spectroscopy (FTIR) to ensure the quality and purity of our MultiLayer graphene flakes. FTIR is a powerful technique that allows us to analyze the molecular composition and identify functional groups present in the graphene flakes. By measuring the absorption and transmission of infrared light, we can detect any impurities or contaminants that may affect the performance and integrity of the graphene flakes. This precise control over the purity of our graphene production enables us to deliver high-quality flakes that meet the stringent requirements of various industries and applications. With FTIR as a key tool in our quality control process, we can confidently provide graphene solutions that exceed our customers’ expectations.

Elevate Your Innovations with High-Quality of MultiLayer Graphene Flakes Powder

Unleash the Future Today!

Why Choose NanoEMI's Graphene Powder?

Discover the Finest Graphene Powder by NanoEMI: Unleash the Power of Pure Graphene.

Pure Graphene Excellence

Immerse yourself in the unparalleled quality of NanoEMI's Graphene Powder. Our product is derived from pure graphene, ensuring optimal performance and outstanding properties. Experience the extraordinary conductivity, mechanical strength, and flexibility that pure graphene offers.

Unrivaled Purity and Consistency

At NanoEMI, we prioritize precision and consistency in our manufacturing process. Our Graphene Powder is produced using cutting-edge techniques, resulting in a highly pure and uniform product. Count on NanoEMI for reliability and reproducibility in every application.

Versatile Applications

Unlock endless possibilities with NanoEMI's Graphene Powder. Its remarkable properties make it an ideal choice for various industries, including electronics, energy, composites, and more. Explore the potential of pure graphene in enhancing conductivity, improving mechanical strength, and enabling innovative solutions.

NanoEMI proudly presents its premium Graphene Powder, meticulously crafted to deliver exceptional results.

Quality Control for Graphene Powder: Key Considerations

At NanoEMI, quality is our top priority. We take great care to ensure the highest standards of quality and reproducibility for our graphene powder. When it comes to graphene powder, ensuring the highest quality is paramount.

Here are the key aspects to consider during the quality control process:

Purity:

Thoroughly assess the purity of the graphene powder, aiming for minimal impurities and contaminants that could affect its performance.

Layer Thickness:

Determine and verify the desired layer thickness of the graphene powder, whether it's single-layer graphene or few-layer graphene, to meet specific application requirements.

Morphology:

Inspect the size, shape, and uniformity of the graphene flakes in the powder. Look for well-defined flakes that exhibit consistent morphology.

Dispersion Quality:

Evaluate the dispersibility of the graphene powder in different solvents or matrices. Optimal dispersion ensures ease of integration into various applications.

Structural Integrity:

Verify the structural integrity of the graphene flakes within the powder to ensure they are not damaged or fragmented during production or handling.

Characterization Data:

Request and review comprehensive characterization data, including information on flake size distribution, surface area, conductivity, and other relevant parameters.

Impurity Analysis:

Perform thorough analysis to identify and quantify any impurities present in the graphene powder, ensuring it meets the required purity standards.

Production Method:

Understand and validate the production method employed to manufacture the graphene powder. Different methods may yield variations in quality and performance.

Quality Consistency:

Implement robust quality control procedures to maintain consistency in the graphene powder's quality from batch to batch.

Compliance and Certification:

Ensure that the graphene powder meets relevant industry standards and certifications, providing assurance of its quality and suitability for specific applications.

By diligently monitoring and controlling these aspects, you can ensure that the graphene powder you choose meets the highest quality standards, enabling optimal performance and unlocking its vast potential in various applications.

Applications of MultilayerLayer Graphene (MLG) flakes powder

In the ever-evolving world of advanced materials, high-quality graphene flakes have emerged as a game-changer with their exceptional properties and extensive range of applications. As the demand for graphene continues to soar across various industries, it is crucial to explore the market for premium-grade graphene flakes.By understanding the transformative capabilities of top-tier graphene flakes, we can unlock new frontiers of innovation and drive progress in diverse sectors.

Here are some of the applications of Multilayer Layer Graphene (MLG) flakes powder:

Electronics:

MLG flakes powder is used in electronic devices such as transistors, sensors, and conductive films, due to its exceptional electrical properties and high carrier mobility.

Energy Storage - battery:

MLG flakes powder is utilized in batteries, supercapacitors, and fuel cells to improve energy storage capacity, charge/discharge rates, and overall performance.

Composite Materials:

MLG flakes powder is incorporated into polymer composites, enhancing mechanical strength, electrical conductivity, and thermal properties.

Biomedical Engineering:

MLG flakes powder finds applications in drug delivery systems, tissue engineering, biosensors, and bioimaging, owing to its biocompatibility and unique properties.

Catalysis:

MLG flakes powder acts as a catalyst support, facilitating various catalytic reactions, including water splitting, hydrogenation, and carbon dioxide reduction.

Flexible Displays:

MLG flakes powder enables the development of flexible and transparent displays, offering improved flexibility, durability, and conductivity.

Coatings and Films:

MLG flakes powder is utilized in coatings and films to enhance mechanical strength, electrical conductivity, and barrier properties against moisture and gases.

Environmental Remediation:

MLG flakes powder is employed in water and air purification systems, facilitating the removal of pollutants and improving filtration efficiency.

Thermal Management:

MLG flakes powder is incorporated into thermal interface materials, heat sinks, and coatings to enhance heat dissipation and thermal conductivity.

Aerospace and Automotive:

MLG flakes powder finds applications in lightweight materials, composites, and coatings for aerospace and automotive industries, enhancing fuel efficiency and mechanical properties.

These are just a few examples of the wide range of applications where Multilayer Graphene (MLG) flakes powder can be utilized. The unique properties of MLG make it a versatile material with immense potential for innovation and advancements in various industries.

Reviews

There are no reviews yet.