Advanced graphene composites

NanoEmi is a graphene nanocomposites producer

NanoEmi is a leading producer of advanced graphene composites, offering innovative solutions for a wide range of industries. With a wide range of applications, from energy storage to electronics and biodevices, our graphene nanocomposites are the solution for a sustainable future.

Our advanced composites are designed to meet your specific needs. At NanoEmi, we specialize in producing EMI shielging advanced graphene composites that offer superior strength, durability, and performance.

Our team of experts is dedicated to pushing the boundaries of what's possible with graphene, and we're excited to share our innovative products with you.

Contact us today to learn more.

Get on the train with the most advanced nanocomposites produced from graphene flakes

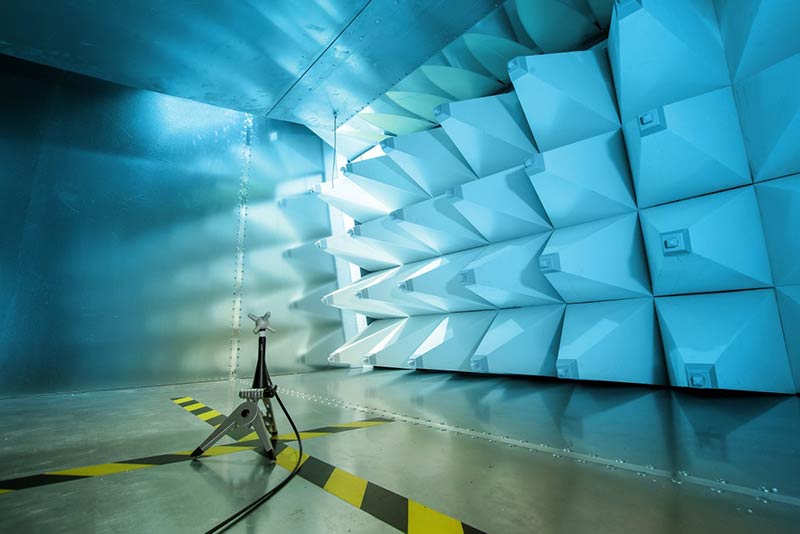

Emigraph - EMI Composite Shields

Emigraph – Composite sheets materials are our flagship products. We developed proprietary technology which allows us to achieve very efficient shielding of electromagnetic radiation:

70 dB / 1 mm of sample

This allows to dump most of the radiation impinging the blocker or enclosure of the device made from our material.

NanoEmi shielding efficiency composites

Discover the power of Emigraph -

nanocomposite EMI shielding sheets by nanoEMI

See how the advanced graphene composite blocks electromagnetic radiation

Power of Composite Materials

CAPEX effort minimized

While implementing new technologies it is always of crucial importance to consider CAPEX expenditures to implement the new solution in your current production process. Our materials are made to work with standard industrial equipment. So if you already have some equipment most probably our material will work with it without the need to make further investment.

Reflection is no longer a key issue

The majority of radiation is absorbed instead of refl ected as in current technologies. In our experiments and in measurements performed by independent laboratories we have confi rmed that even 70% of intensity of radiation is absorbed while only 30% is refl ected.

Frequency range

Reduction of mass

Get on the train with the most advanced nanocomposites produced from graphene flakes

Mass reduction in the most advanced graphene nanocomposites refers to the ability to create materials that are lightweight yet strong by incorporating graphene into a composite material. Graphene, being the thinnest and lightest material known, has exceptional mechanical properties such as high tensile strength and stiffness. By combining graphene with other materials, such as polymers, metals or ceramics, it is possible to produce composites that are significantly lighter than conventional materials without compromising on their strength or stiffness. This is of critical importance for a number of applications where consumption of electrical energy or of fossil fuels has to be reduced. These advanced graphene nanocomposites have numerous potential applications in industries such as aerospace, automotive, and sports equipment where weight reduction is critical.

When compared to key competitive materials our

composite is roughly:

11x lighter than lead (Pb)

Our composite is significantly lighter than lead, with a density of around 1 grams per cubic centimeter (g/cm³) compared to lead's density of 11.34 g/cm³. This means that composite is approximately 11 times lighter than lead.

9x lighter than copper (Cu)

Our composite is actually significantly lighter than copper, with a density of around 1 grams per cubic centimeter (g/cm³) compared to copper's density of 8.96 g/cm³. This means that composite is approximately 9 times lighter than copper.

3x lighter than aluminum (Al)

Our composite is actually significantly lighter than aluminum, with a density of around 1 grams per cubic centimeter (g/cm³) compared to aluminum's density of 2.70 g/cm³. This means that composite is approximately 3 times lighter than aluminum.